Files

|

Type

|

Format

|

Title

|

Edition

|

Description

|

Author

|

Availability

|

Size

|

|---|---|---|---|---|---|---|---|

| Paper | application/pdf |

A Semi-Quantitative Approach Development for Risk-Based Inspection in a Petrochemical Plant |

2020 |

The provided method in this study is a management tool to recognize and then prioritize the equipment’s risks and, consequently, propose an inspection plan based on these risks. In fact, it is a risk analysis aspect of an inspection plan for industrial equipment. The study is performed on de-ethanizer unit, considering variety of process equipment including distillation tower, exchanger, pressure vessel, drum, and related piping. |

Davood Eskandari, Hossein Charkhand, and Abdollah Gholami |

Upon Request |

476 KB |

| Paper | application/pdf |

AB-505 Risk Based Inspection Requirements for Pressure Equipment |

2005 |

The purpose of this document is to promote and maintain pressure equipment safety by defining the essential elements to be addressed in a RBI program. Through the use of these guidelines, it is intended that RBI programs will be applied correctly based on sound judgement and principles, such that the inherent fiscal and operational benefits of RBI can be realized and pressure equipment safety enhanced. |

ABSA |

Upon Request |

23 KB |

| Presentation | application/pdf |

Aging, Overworked, Debottlenecked Refineries- an increased Risk to the Insurance Industry |

N/A |

The Contents of this Presentation include: •Challenges in the Refining Industry •Risk Management •Risk Based Inspection •Managing Effects of Aging •Management of Debottlenecking •Workload Management In the context of corrosion and pressure vessel integrity assurance |

Alfred.A.Kruijer |

Free |

116 KB |

| S | application/pdf |

API 510 -Pressure Vessel Inspection Code- In-service Inspection, Rating, Repair, and Alteration |

2018 |

This inspection code covers the in-service inspection, repair, alteration, and rerating activities for pressure vessels and the pressure-relieving devices protecting these vessels. This inspection code applies to all hydrocarbon and chemical process vessels that have been placed in service |

API |

Upon Request |

368 KB |

| S | application/pdf |

API 571 -Damage Mechanisms Affecting Fixed Equipment in the Refining Industry |

2020 |

This recommended practice discusses damage mechanisms applicable to oil refineries; however, much of the information herein can also be applied to petrochemical and other industrial applications, as the user deems appropriate. It is up to the user to determine the applicability and appropriateness of the information contained herein as it applies to their facility. |

API |

Upon Request |

8,308 KB |

| S | application/pdf |

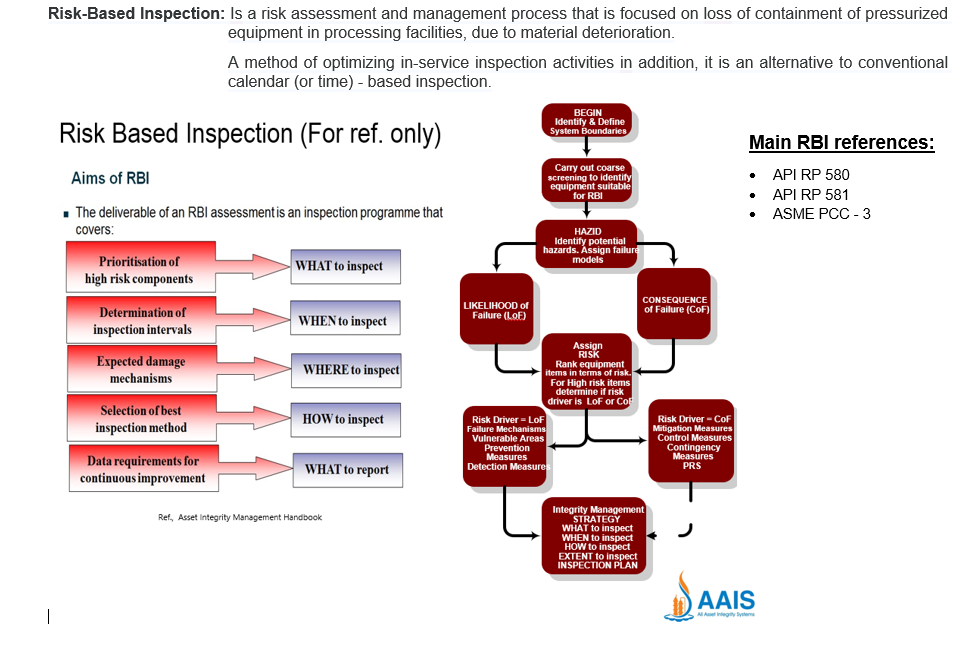

API 580-Risk-based Inspection |

2016 |

The purpose of this document is to provide users with the basic minimum and recommended elements for developing, implementing, and maintaining a RBI program. It also provides guidance to owner-users, operators, and designers of pressure-containing equipment for developing and implementing an inspection program. These guidelines include means for assessing an inspection program and its plan. The approach emphasizes safe and reliable operation through risk-prioritized inspection. |

API |

Upon Request |

389 KB |

| RP | application/pdf |

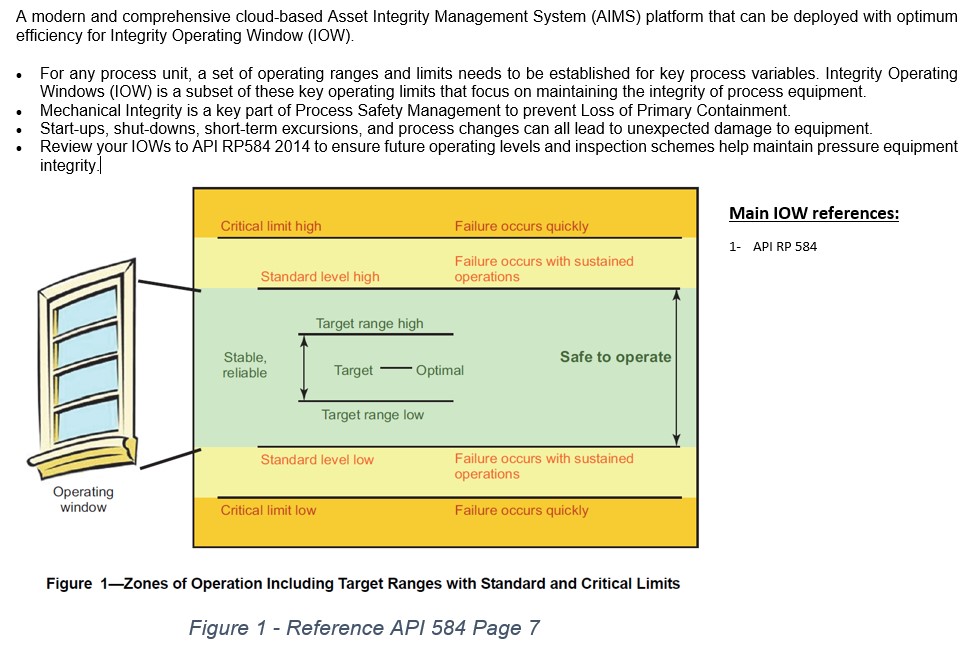

API 584 - Integrity Operating Windows -IOW |

2014 |

The purpose of this recommended practice (RP) is to explain the importance of integrity operating windows (IOW’s) for process safety management and to guide users in how to establish and implement an IOW program for refining and petrochemical process facilities for the express purpose of avoiding unexpected equipment degradation that could lead to loss of containment |

API |

Upon Request |

390 KB |

| S | application/pdf |

API 653- Tank Inspection, Repair, Alteration and Reconstruction |

2020 |

This standard covers steel storage tanks built to API 650 and its predecessor API 12C. It provides minimum requirements for maintaining the integrity of such tanks after they have been placed in service and addresses inspection, repair, alteration, relocation, and reconstruction. |

API |

Upon Request |

1,450 KB |

| S | application/pdf |

ASME PCC-3 - Inspection Planning Using Risk-Based Methods |

2017 |

This Standard provides information on using risk analysis to develop and plan an effective inspection strategy. Inspection planning is a systematic process that begins with identification of facilities or equipment and culminates in an inspection plan. Both the probability of failure and the consequence of failure should be evaluated by considering all credible damage mechanisms that could be expected to affect the facilities or equipment. |

ASME |

Upon Request |

1,266 KB |

| HB | application/pdf |

Asset Integrity Management Handbook |

2015 |

This book arose from a series of papers and procedures in the Asset Integrity Management system for an aging offshore oil field infrastructure the data on degradation modes and Asset Integrity Management principles are gathered here |

Peter McClean Millar |

Upon Request |

3,330 KB |

| S | application/pdf |

BS EN 16991 - Risk-Based Inspection Framework |

2018 |

This European Standard specifies the Risk-Based Inspection Framework (RBIF) and gives guidelines for Risk-Based Inspection and Maintenance (RBIM) in hydrocarbon and chemical process industries, power generation and other industries where RBI is applicable. |

BSI |

Upon Request |

952 KB |

| Paper | application/pdf |

Development of the Risk-Based Inspection Techniques and Pilot Plant Activities |

N/A |

This Paper presents the Risk based inspection techniques. The techniques have been developed and applied at a number of pilot plants. Results from the first risk-based inspection pilot plant indicates safety due to pipe failure can be doubled while the inspection reduced to about 80% when compared with current inspection programs. |

Jerry H. Phillips |

Upon Request |

314 KB |

| S | application/pdf |

DNV -OSS-303 - Risk Based Verification |

2001 |

This document provides the basic philosophy and describes the principles, content and implementation of a risk based verification (RBV) approach, DNV’s role and an outline of the deliverables. The RBV approach aims at balancing the efforts to control the operational and technological risks. It provides for cost and time savings in a verification approach by focusing on criticality and corresponding efforts requiring priority attention. |

DNV |

Free |

246 KB |

| S | application/pdf |

DNV-OSS-300 -Risk Based Verification |

2012 |

The main objectives of this document are to: — describe DNV’s Risk Based Verification services — provide a common communication platform for describing the extent of verification activities, i.e. how to define a verification scope — give guidance to owners and other parties for selecting the level of involvement of the verifier — provide an opportunity to establish efficient, cost effective, predictable and transparent verification plans. |

DNV |

Free |

145 KB |

| S | application/pdf |

DNV-OSS-304 Risk Based Verification of Offshore Structures |

2006 |

This specification is intended to be used for specifying verification services for total or part of the structure for offshore installations for all or selected project phases. The document is developed for structures to both fixed and floating platforms, but is also applicable for onshore structures if found relevant |

DNV |

Free |

206 KB |

| RP | application/pdf |

DNVGL-RP-C302 Risk Based on Corrosion Management |

2015 |

This RP discusses an approach to corrosion management based on risk management principles as defined below. Risk-based management is the identification, assessment, and prioritization of risks (defined in ISO 31000 as the effect of uncertainty on objectives, whether positive or negative), followed by coordinated and economical application of resources to minimize, monitor, and control the probability and/or impact of unfortunate events or to maximize the realization of opportunities. |

DNVGL |

Free |

852 KB |

| S | application/pdf |

EEMUA-206-Risk Based Inspection- A Guide to Effective Use of the RBI Process |

2006 |

The objective of producing this document is to give a general guidance for those interested in applying or developing an RBI approach to inspection. This guidance has been produced predominantly for application on pressure systems and equipment, but it is considered that the guidance is also of use to all those involved in risk-based inspection of other mechanical plant |

EEMUA |

Upon Request |

333 KB |

| Presentation | application/pdf |

Introduction to Risk Assessment |

N/A |

This Presentation is a general Overview on the definition of the risk-based inspection |

Metserve |

Free |

402 KB |

| Paper | application/pdf |

Machine Learning Approach for Risk-Based Inspection Screening Assessment |

N/A |

This paper attempts to tackle the RBI challenges by utilizing a machine learning approach to conduct screening assessment. A case study using a dataset of RBI assessment for three onshore and four offshore oil and gas production and processing units is provided, to illustrate the development of an intelligent system, based on a machine learning model for performing RBI screening assessment |

Andika Rachman, R.M. Chandima Ratnayake |

Upon Request |

758 KB |

| Paper | application/pdf |

Opportunities and Threats of Risk Based Inspection - the new Italian Legislation on Pressure Equipment Inspection |

2012 |

The paper presents a method to demonstrate that alternative inspection intervals, resulting from RBI, entail risk levels lower or equal than deterministic inspection intervals. The proposed method fits the requirements of Italian Authorities for RBI exception. Method is also suitable to be exported to other Countries where the legislation is RBI - skeptic |

Valerio Cozzani, Eddy De Rademaeker |

Upon Request |

94 KB |

| HB | application/pdf |

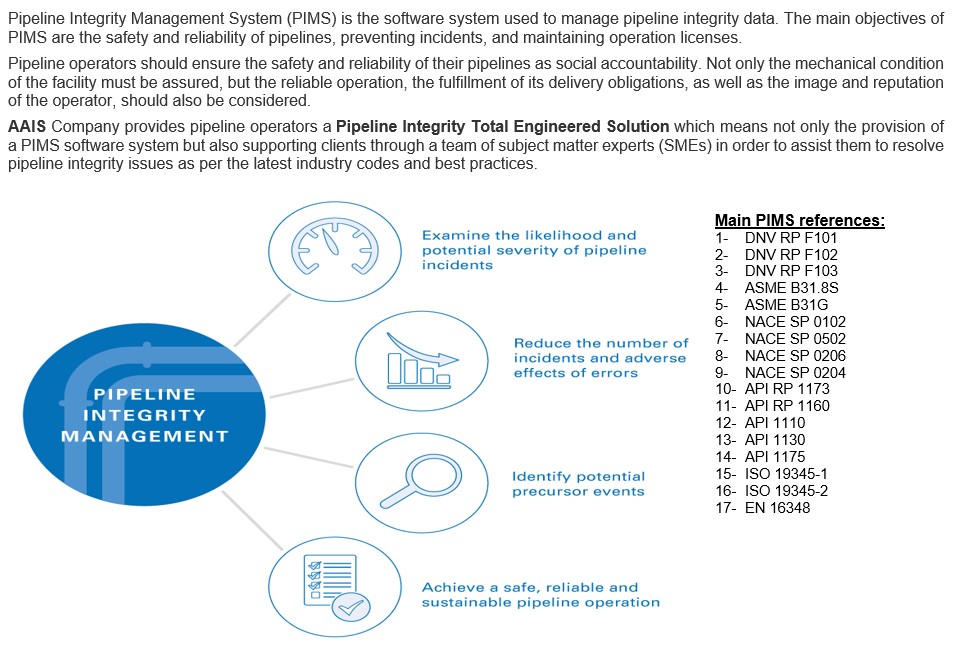

Pipeline Integrity Handbook- Risk Management and Evaluation |

2014 |

There are several information sources on the market on this subject; most of them are regulatory requirements and guidelines. In most cases, due to the very nature, the regulatory materials are specifically tailored as ‘do and don’t’ lists. This rule of thumb hand book is intended to bring closer the management principles and regulatory requirements and to apply these principles to achieve the best possible results. |

Ramesh Singh |

Upon Request |

6,140 KB |

| Presentation | application/pdf |

RBI in Major Plants |

N/A |

This Presentation gives a general overview on the risk-based inspection concept and Guidelines on Risk Assessments |

R.T.Canaway, F.I.Chem.E |

Free |

392 KB |

| Presentation | application/pdf |

RBI-Risk-Based Inspection Reassessment |

N/A |

Purpose of Presentation – Highlight key parts of API 581 and 581 – API 510, 570 and 653 allowance for RBI – Overview RBI implementation steps – RBI Reassessment and & Updating – Discuss the role of the inspector in RBI |

Lynne Kaley |

Free |

461 KB |

| Paper | application/pdf |

Relationship between RBI and Other Risk-Based and Safety Initiatives |

N/A |

This Document shows the main difference between RBI and Other Risk-Based and Safety Initiatives including ( HAZOP, PHA, PSM, RCM , etc..) |

N/A |

Free |

504 KB |

| Paper | application/pdf |

Risk Based Decisions |

2004 |

This Paper gives the basic concept of the risk-based inspection approach including the common International References (mainly ASME and API) and the Risk Matrix illustration |

Barringer & Associates, Inc |

Upon Request |

36 KB |

| Presentation | application/pdf |

Risk Based Inspection -RBI-According API 580 |

N/A |

The Purpose of this presentation is to provide users with the basic elements for developing and implementing a risk-based inspection (RBI) program. |

M. Samy |

Free |

307 KB |

| Paper | application/pdf |

Risk Based Inspection |

2005 |

The objective, principals and practices of Risk Based Inspection are demonstrated and explained. The target audience for this paper is engineers, inspectors and managers who want to understand what Risk Based Inspection is all about, what are the benefits and limitations and how inspection practices can be changed to reduce risks, save costs without impacting safety risk |

Ramesh J. Patel |

Upon Request |

39 KB |

| HB | application/pdf |

Risk Based Inspection (RBI) 580 |

2021 |

The Topics covered here include: • Overview of the Risk Based Inspection (RBI) Module • Overview of the RBI 580 Methodology • About RBI Methodologies • Access the Risk Based Inspection Overview Page • Access the Unit Summary Workspace • Access the Asset Summary Workspace • Access the Asset Summary Workspace for a New |

GE - General Electric Company |

Upon Request |

5,327 KB |

| Paper | application/pdf |

Risk Based Inspection (RBI) Best Practice- The Technical Specification for Engineering Successful Implementation |

2012 |

This Keynote Paper is written to help plant sites wishing to implement Risk Based Inspection (RBI) for the first time to enhance their equipment integrity management practice as well as for those plant sites not satisfied with their existing Risk Based Inspection (RBI) process at site and considering a change. |

Ron Selva |

Upon Request |

450 KB |

| Presentation | application/pdf |

Risk Based Inspection (RBI) Planning for Hull Structures of Mobile Offshore Units |

N/A |

This Presentation gives a general overview on the risk-based inspection for structures of mobile offshore units including the typical overview on the Methodology of the RBI |

Madhu Parlapalli, David Baxter |

Free |

810 KB |

| Presentation | application/pdf |

Risk Based Inspection (RBI) |

2011 |

The Contents of this Presentation include: -Introduction - Corrosion Management -What is Risk Based Inspection (RBI)? -How to perform a RBI analysis? -What importance has the probability of detection (POD) of a crack/initiation point? |

Roy Johnsen |

Free |

1,216 KB |

| Paper | application/pdf |

Risk Based Inspection Approach for effective Monitoring remaining life for Integrity of Refinery Equipment |

N/A |

This paper explains the areas to consider making RBI assessment effective that can help overrule all traditional calculations of predicting remaining life of Refinery equipment as Pressure Vessels, Above ground storage Tanks and process piping. Upon RBI assessment an effective Management of Change (MOC) can be considered to improve the safety of plant. |

Prashant V. WAGH |

Upon Request |

280 KB |

| Presentation | application/pdf |

Risk Based Inspection, Beyond Implementation to Integration |

2003 |

The Outline of this Presentation includes: • Introduction to RBI • API RBI Overview (API 581) • API RP 580 Brief Overview • Link with RP 579 FFS • Brief on Status of RP 571 Damage Mechanisms • Interaction with exiting Codes & Standards (API 510, 579 & 653) • Direction of API RBI User Group Activities |

The Equity Engineering Group |

Free |

145 KB |

| Paper | application/pdf |

Risk Based Maintenance for Offshore Wind Structures |

2013 |

This paper describes the use of inspection reliability information in fitness-for-service and criticality assessments for offshore structures. Assessments of components that have never been inspected should assume a defect distribution from manufacturing quality assurance reports taking into account any propagation of damage that might have occurred. |

Feargal Brennan And Elsevier B.V. |

Upon Request |

242 KB |

| Paper | application/pdf |

Strategies for Risk Based Inspection of Corrosion Damage in Pipeline Systems |

2019 |

Pipes and other assets at oil refineries are subject to internal corrosion over time. The corrosion can, if not carefully monitored, cause leakages and other substantial and costly damages. Regular inspection of the pipes is therefore necessary to monitor the corrosion development. However, inspections are also costly and time-consuming, and for these reasons the aim of performing a risk-based inspection is presented |

Anders Hjort |

Free |

973 KB |

| HB | application/pdf |

Subsea Pipeline Integrity and Risk Management |

2014 |

This new book “Subsea Pipeline Integrity and Risk Management” reflects upon the new pipeline technologies in integrity and risk management developed by the oil and gas industry, where the authors apply them in design, consulting and integrity management. This book is written for engineers who work in the field of subsea pipeline engineering. |

Yong Bai Qiang Bai |

Upon Request |

9,632 KB |

| GL | application/pdf |

TWI-Risk Based Inspection (RBI) based on API 580 |

2002 |

This Document shows the basic concept of the risk based inspection approach, Consequence and Probability for Risk-Based Inspection, Planning the RBI Assessment, Data and Information Collection for RBI Assessment , Identifying Deterioration Mechanisms and Failure Modes, and RBI Documentation and Record-keeping |

TWI |

Upon Request |

423 KB |