Tanks

|

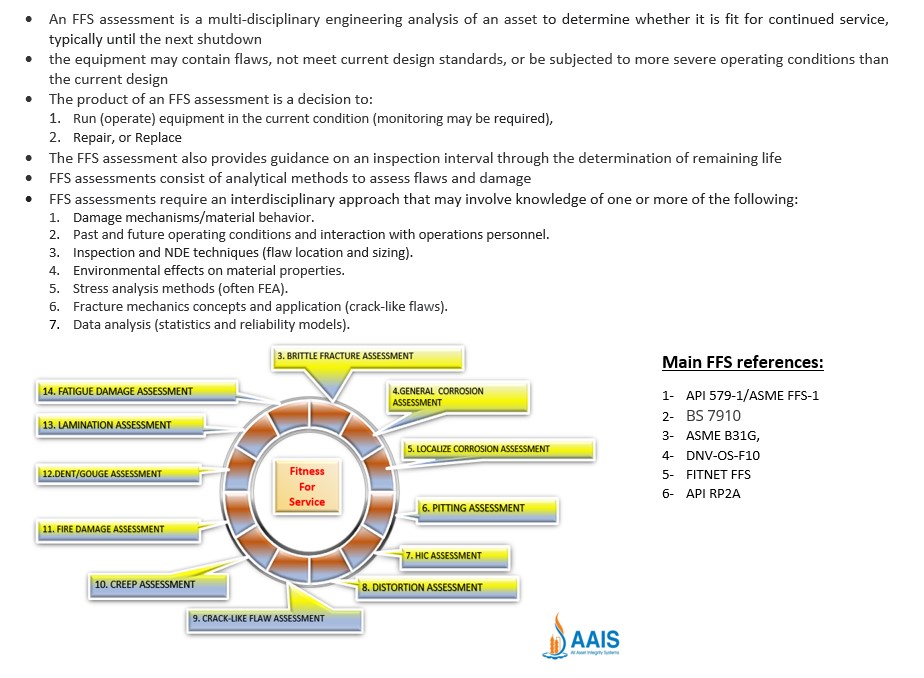

Fitness-for-Service (FFS) is an assessment that is carried out using standardized methods and criteria, that evaluates the structural integrity of an asset/component to determine whether the asset/component is suitable for its intended use. The Fitness-for-Service (FFS) assessment provides a quantitative measure of structural integrity and is part of asset integrity management. The assessments are used to highlight the need for replacement or repair of assets/components. Two of the most commonly used are the recommended practice for assessing fitness-for-service published by the American Petroleum Institute (API) in API 579 and the guidance for the assessment of defects metallic structures published by British Standards in BS 7910. |

|

S. |

Type |

Format |

Title |

Ed. |

Scope |

Author(s) |

Availability |

|

1 |

S |

|

2021 |

This Standard provides guidance for Conducting FFS assessments using methodologies specifically prepared for pressurized equipment the guidelines provided in this Standard can be used to make run-repair-replace decisions to help determine if components in pressurized equipment containing flaws that have been identified by inspection can continue to operate safely for some period of time. |

API |

Upon Request |

|

|

2 |

S |

|

2020 |

This Standard Establishes the minimum requirements for material, design, fabrication, erection , and inspection for vertical , cylindrical, above ground, closed and open top welded storage tanks in various sizes and capacities for internal pressures approximating Atmospheric pressure |

API |

Upon Request |

|

|

3 |

S |

|

API 653- Tank Inspection, Repair, Alteration and Reconstruction |

2020 |

This standard covers steel storage tanks built to API 650 and its predecessor API 12C. It provides minimum requirements for maintaining the integrity of such tanks after they have been placed in service and addresses inspection, repair, alteration, relocation, and reconstruction. |

API |

Upon Request |

|

4 |

S |

|

API RP 652-Linings of Aboveground Petroleum Storage Tank Bottoms |

2020 |

This recommended practice (RP) provides guidance on achieving effective corrosion control in aboveground storage tanks by application of tank bottom linings. It contains information pertinent to the selection of lining materials, surface preparation, lining application, cure, and inspection of tank bottom linings for existing and new storage tanks. In many cases, tank bottom linings have proven to be an effective method of preventing internal corrosion of steel tank bottoms. |

API |

Upon Request |

|

5 |

GL |

|

|

This guide provides fitness for service assessment methodology applicable to existing pressure vessels, storage tanks and piping |

Exxon |

Upon Request |

|

|

6 |

HB |

|

Fitness-for-Service and Integrity of Piping, Vessels and Tanks |

2005 |

This Book provides instruction on the latest ASME recommended practices for inspecting, evaluating, and monitoring pressure vessels and piping. This handy volume annotates and explains ASME code and API inspection and fitness-for-service practices. Presented in a clear, precise manner, this comprehensive guide meticulously explains how stress analysis, materials, engineering, and nondestructive inspection affect fitness-for-service |

George Antaki |

Upon Request |

|

7 |

Paper |

|

|

In this article, the application of the API 579 Fitness for service procedures to Above ground storage tanks will be discussed |

Joel Andreani and Katelyn Gustoff |

Upon Request |

|

|

8 |

Paper |

|

2018 |

This article provides a case study that illustrates how European design standard “glass reinforced plastic (GRP) tanks for use above ground”, designation EN 13121 [1] (EN 13121) can be used to calculate expected changes in FRP for FRP vessels. The case incorporates both destructive test results and non-destructive, non-intrusive results |

Geoff Clarkson |

Upon Request |