-

Material Comparative

-

Design Review / Design Validation / As Built Drawing Descr

-

Material Identification

-

Material Testing

-

Corrosion Tests Desc

-

NDT Selection Desc

-

Non-Metallic Composite Repair

-

Failure Analysis Module Desc

-

Design Review / Design Validation / As Built Drawing

-

Material Selection

-

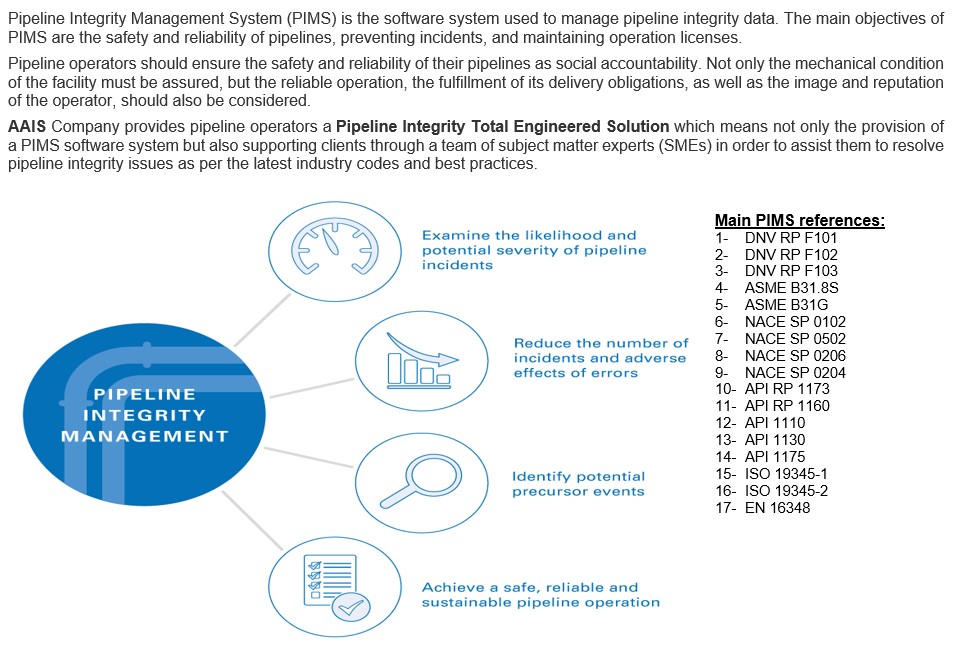

Pipeline system Design

-

Corrosion Module

-

Material Control Descr

-

Repair Integrity Management System

Repair Integrity Management System

-

Material Failure

-

Coating and Insulation Desc

-

Conventional Method Desc

-

Pressure Vessels Calculations

-

Metal Analyzers

-

Welding Repair

-

Steel Structure

-

Mechanical Repair

-

Corrosion Management and Control

Corrosion Management and Control Desc

-

Steel Structure Calculations

-

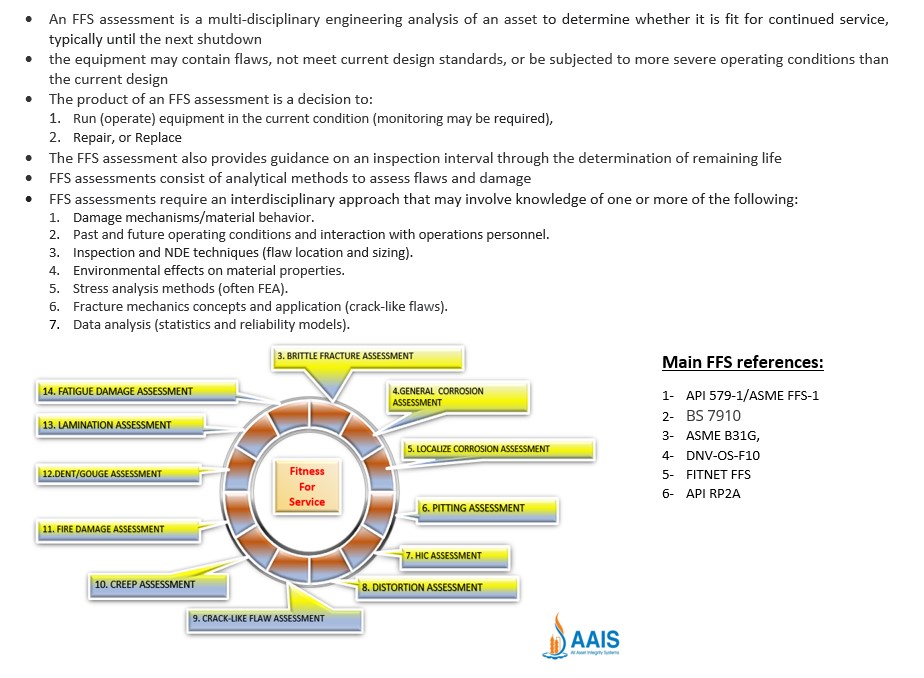

FFS References

-

Heat Treatment Desc

-

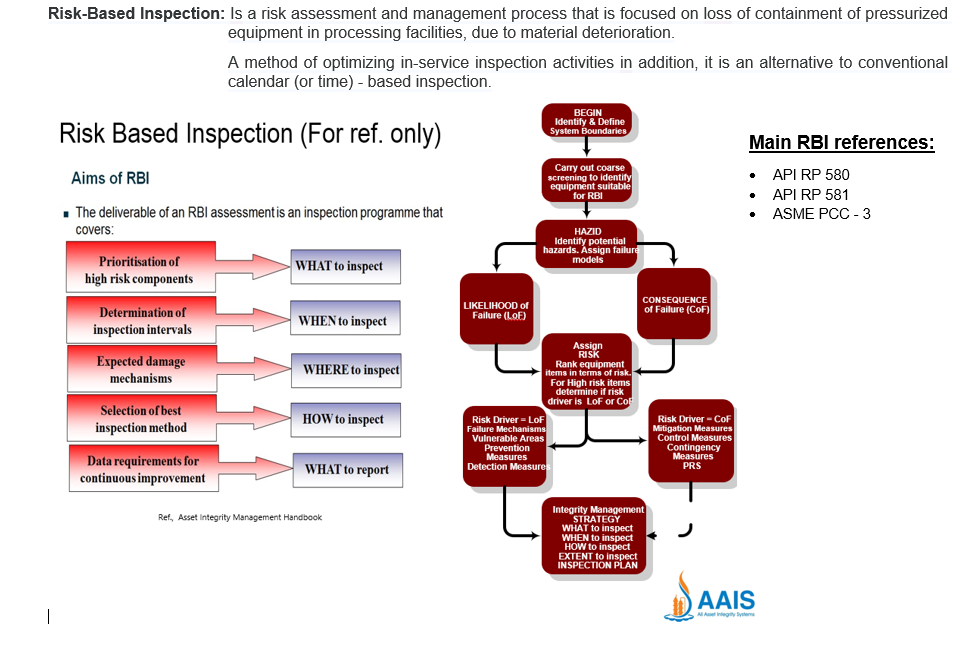

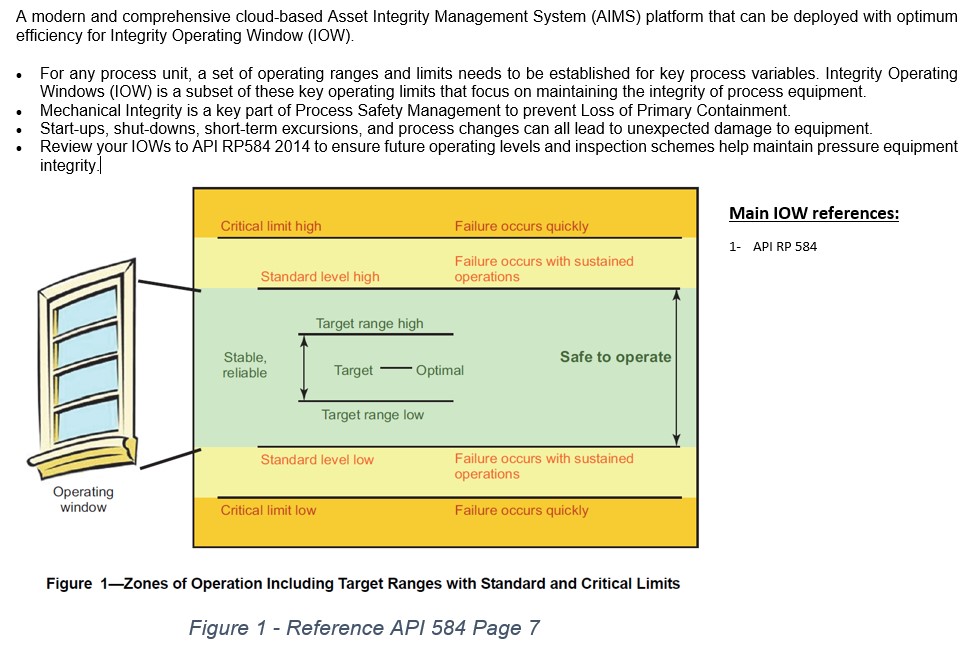

RBI Concept & Requirements

-

Corrosion Types and damage mechanism

Corrosion Types and damage mechanism Desc

-

Corrosion Module Corrosion Tests Desc

-

Corrosion Material Desc

-

Design Review / Design Validation / As Built Drawing

-

Welding Calculations

-

Hot Tapping & In-service Weld

-

Non-Conventional Methods Desc

-

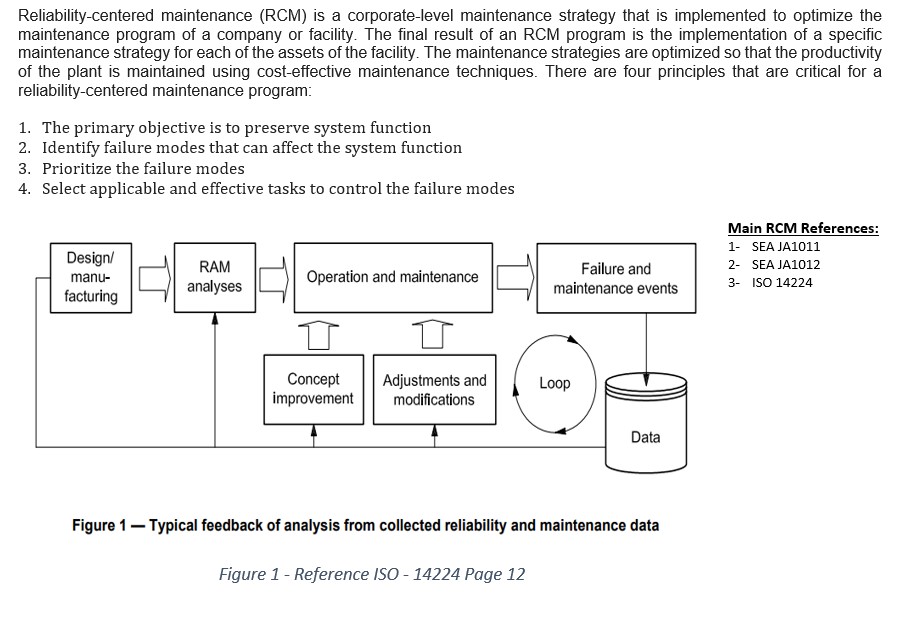

RBI Methodology

-

Piping Systems Calculations

Brief

AAIS is conducting online training for Certified Non-Destructive Testing (NDT) Professional Level 1 Course.

This course gives students an overview of the non-destructive and destructive assessment methods used in weld evaluation.

This procedure includes learning the principles of various NDT methods, as well as the importance of NDT, applications,

limitations of NDT methods and techniques, and codes, standards, and specifications linked to non-destructive testing technology.

Students will also learn about essential quality assurance and quality control criteria based on ASQ, ASME, and ANSI guidelines.